From concept to turnkey solutions

The product range contains Compnents, Stand-alone Systems, semiautomatic desk-robots und full-automatic productioncells oder -lines.

Test laboratories

In the soldering and dispensing laboratorieslaboratories, the physical properties of the applications and other elements are studied. Based on this analysis, the most appropriate mta® soldering or dispensing techniques can be defined for each specific application.

Point to point selective soldering

With the point to point selective soldering technique, very specific points to be soldered can be selected. Compared to soldering on defined areas, this enables a higher accuracy and the possibility of adapting the soldering parameters to the requirements of each individual point.

As alternative to manual soldering, the point to point soldering automated solutions guarantee a high soldering quality as they are much more repeatable and reliable than working with soldering operators.

After a complete analysis, the most appropriate soldering technique is chosen from the mta® product range: soldering iron, laser, induction or microflame.

All of the above mentioned soldering techniques can be integrated into the various mta® standard platforms,

|

Volumetric dispensing The mta® high-precision volumetric dispensers offer the most accurate volume control available in the fluid dispensing industry. They enable perfect repeatability of micro-volumes to be dispensed starting with 0.1 mm³. |

|

Soldering & dispensing standard platforms |

|

FRC500-Dual robotic cell The PC controlled FRC500-Dual standard robotic cell can be used for semi or fully automatic operations of selective point to point soldering from above as well as volumetric dispensing operations. The FRC500-Dual concept allows parallel processes to be carried out on a single platform which increases productivity and optimizes the cycle time. |

|

TR300 table-top robot The PC controlled TR300 standard table-top robot can be used for semi-automatic operations of selective point to point soldering from above as well as volumetric dispensing operations. |

|

|

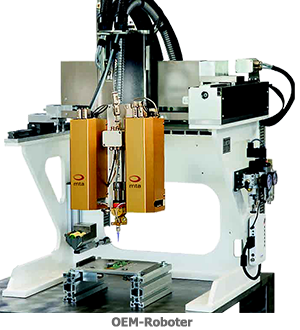

OEM robot for integrator The PC controlled OEM standard robot can be used for semi or fully automatic operations of selective point to point soldering from above and volumetric dispensing operations. With its flexible and modular concept, the OEM robot can be fully and easily integrated into a production line. |

|

Assembly line example Product |